Carving in granite can be a challenging task that requires precision and patience. The success of the project depends on the type of carbide used to create the chisel. Carbides come in different types, each with its unique properties and applications.

(What Tipe Of Carbide Is Used To Fabricate Chiesels To Carve In Granite ?)

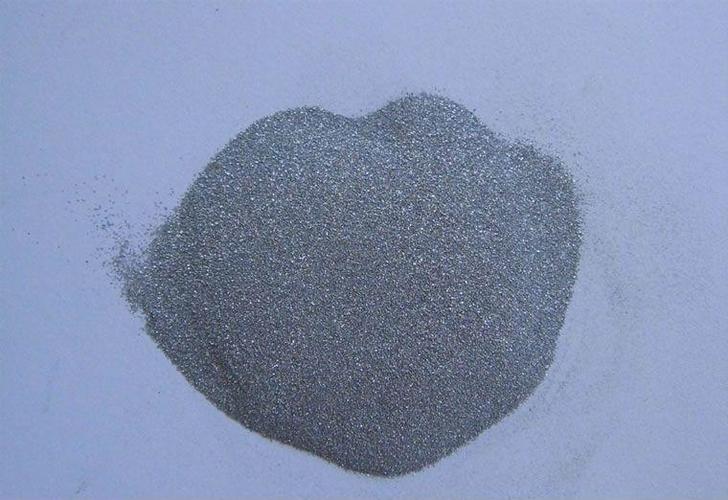

One of the most popular types of carbide used for cutting granite is diamond-carbide. Diamond-carbide has a very sharp edge and is able to cut through granite with great accuracy. It also provides excellent wear resistance, making it ideal for use in extreme conditions such as high heat or heavy use.

Another type of carbide commonly used in granite carving is molybdenum carbide (Mo-C). Mo-C is known for its high strength-to-weight ratio, which makes it well-suited for use in tasks where weight is critical. It also has good corrosion resistance, making it an ideal choice for use in outdoor environments.

Carbon fiber carbide (CF) is another popular option for granite carving. CF is lightweight and durable, making it an ideal choice for use in tasks where weight is not a concern. It also has good resistance to scratching and chips, making it a reliable choice for use in granite carving.

(What Tipe Of Carbide Is Used To Fabricate Chiesels To Carve In Granite ?)

In conclusion, the type of carbide used to fabricate chimes to carve in granite can have a significant impact on the final product’s quality and durability. Whether you prefer the sharp edges of diamond-carbide, the high strength-to-weight ratio of Mo-C, the lightweight and durable nature of CF, or the corrosion-resistant properties of Mo-C, there is a carbide out there that will meet your needs. When choosing the right carbide, consider factors such as cost, compatibility with other materials, and the specific application requirements of the job at hand. With the right choice of carbide, you can achieve beautiful, long-lasting results from your granite carving projects.