Title: How to Understand the Secret Behind Tungsten Carbide Burs?

(Technical Insight: Key Facts About Tungsten Carbide Burs)

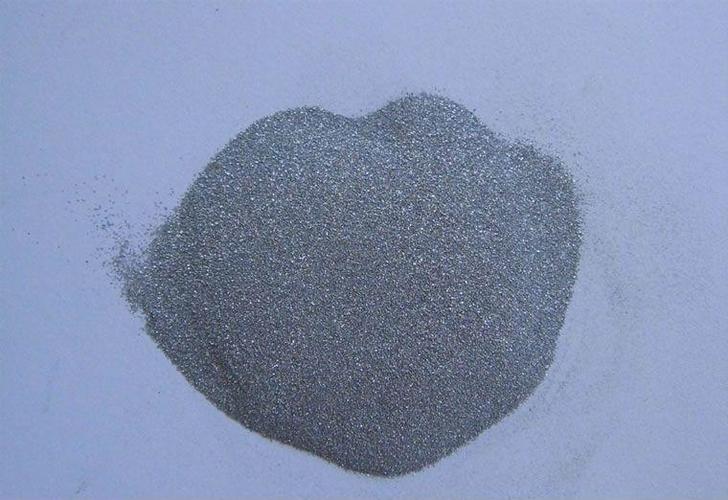

The world of metals has never been more complex than it is today. One such element that holds the key to all technological advancements lies in tungsten carbide (TWC). While tungsten carbide may seem like a waste material to many, it has remarkable properties that make it an essential part of many industrial applications.

Tungsten carbide is one of the most widely used materials in the world for construction, engineering, and automotive industries. It is primarily composed of two atomic components – tungsten and carbon dioxide. The tungsten component serves as the backbone of the crystal structure, while the carbon dioxide provides the electrical conductivity and thermal stability of the material.

According to experts, tungsten carbide has exceptional properties that make it ideal for a wide range of applications. For example, it can be used to make lightweight, durable, and resistant to corrosion materials. Additionally, it is known for its high melting point, which makes it suitable for use in high-temperature applications. Furthermore, tungsten carbide has excellent thermal conductivity, which allows it to maintain a consistent temperature over long periods of time without fatigue or damage.

Another fascinating aspect of tungsten carbide is its unique chemical composition. The compound consists of two separate elements, each responsible for its own unique properties. Tungsten is a element that readily reacts with carbon dioxide to formnides, resulting in a high melting point and good strength. This property makes tungsten carbide well-suited for use in materials that require a strong bond between atoms.

Despite its immense potential, tungsten carbide has not yet found widespread adoption due to several factors. One reason is the cost of production. Tungsten carbide is expensive to produce due to the complexity of the crystal structure and the need for specialized equipment. Additionally, there is a lack of market demand for tungsten carbide due to its poor thermal conductivity and low resistance to corrosion.

(Technical Insight: Key Facts About Tungsten Carbide Burs)

Despite these challenges, tungsten carbide continues to gain popularity in the technology industry. Many companies have invested heavily in research and development to improve the performance of tungsten carbide and make it even more accessible to end-users. With continued innovation and development, we can expect to see more innovative products and applications of tungsten carbide in the years to come.

Inquiry us

if you want to want to know more, please feel free to contact us. (nanotrun@yahoo.com)