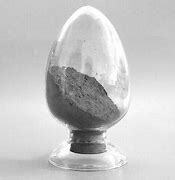

Overview of Metallurgy Silicon Carbide /Sic Powder/Lump 90

Silicon Carbide (SiC), also known as carborundum, is a synthetic ceramic compound made up of silicon and carbon atoms. Known for its exceptional hardness, thermal conductivity, and resistance to chemical reactions and wear, SiC is a versatile material widely used in high-performance applications that demand superior physical and electronic properties. Its unique crystal structure, which can exist in several polytypes, contributes to its multifaceted utility across various industries.

Features of Metallurgy Silicon Carbide /Sic Powder/Lump 90

-

Exceptional Hardness: Silicon carbide ranks just below diamond and boron carbide in hardness, making it an ideal abrasive material.

-

High Thermal Conductivity: It is an excellent heat conductor, capable of dissipating heat rapidly, which is crucial for high-power electronic and semiconductor devices.

-

Chemical Stability: Resistant to most acids, alkalis, and salt solutions, SiC maintains its properties even under harsh chemical environments.

-

Wide Bandgap Semiconducting Material: As a wide bandgap semiconductor, it operates at higher temperatures and frequencies than conventional semiconductors like silicon.

-

Mechanical Strength and Wear Resistance: Offers high mechanical strength and excellent wear resistance, suitable for mechanical seals, bearings, and pump components.

-

Thermal Shock Resistance: Can withstand rapid temperature changes without cracking or degrading, important for applications involving cyclic heating and cooling.

(Metallurgy Silicon Carbide /Sic Powder/Lump 90)

Parameters of Metallurgy Silicon Carbide /Sic Powder/Lump 90

Silicon carbide (SiC powder) is a highly refine powder that has been used in the development of various metallic and plastic. The precise quantity and composition of SiC powder can have significant impacts on its properties, such as its ability to form high-temperature contacts with materials, improve wear resistance, and enhance the mechanical strength of certain types of composites.

The metallurgical process of silico carbide powder typically involves melting Silico carbide under high heat and pressure to obtain a solid mass of 90 parts per million (ppm). Once the powders are isolated from the melting medium, they are crushed and ground into fine powder using a mix of sieving machines.

To determine the precise amount of SiC powder required for specific applications, such as contact or mechanical strength improvement, it is essential to use a precise measurement tool. This may involve adding or subtracting a specific percentage of the total volume of the powder from the initial mass to obtain the desired amount.

Another important parameter in determining the amount of SiC powder required for specific applications is the type of metal being used. For example, SiC powder may be needed for the fabrication of high-speed bolted alloys, while other compounds may require different amounts.

In summary, the use of Silico carbide powder can provide high-temperature contacts, improved wear resistance, and enhanced mechanical strength for various metallic and plastic. However, the precise quantity and composition of SiC powder requires careful consideration to ensure optimal performance in given applications.

(Metallurgy Silicon Carbide /Sic Powder/Lump 90)

Applications of Metallurgy Silicon Carbide /Sic Powder/Lump 90

-

Semiconductor Devices: Used in high-voltage, high-frequency, and high-temperature power electronics, such as MOSFETs, Schottky diodes, and power modules.

-

Abrasive Materials: As an abrasive grain in grinding wheels, sandpapers, and cutting tools due to its hardness and wear resistance.

-

Refractories and Furnace Linings: In high-temperature furnaces and kilns because of its outstanding thermal stability and resistance to corrosion.

-

Ceramic Armor: In lightweight armor systems due to its combination of hardness, toughness, and low density.

-

Chemical Process Equipment: For pumps, valves, and seals in corrosive chemical environments where metals would corrode.

-

Wire Sawing: As the abrasive medium in wire saws for slicing silicon wafers in the semiconductor industry and gemstones.

Company Profile

MyCarbides is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality carbides and relative products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality carbide materials and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

FAQs of Metallurgy Silicon Carbide /Sic Powder/Lump 90

Q: How is Metallurgy Silicon Carbide /Sic Powder/Lump 90 produced?

A: Metallurgy Silicon Carbide /Sic Powder/Lump 90 is primarily synthesized through the Acheson process, which involves heating a mixture of silica sand and carbon (usually in the form of coke) in an electric furnace at high temperatures.

Q: Is Metallurgy Silicon Carbide /Sic Powder/Lump 90 conductive?

A: Yes, Metallurgy Silicon Carbide /Sic Powder/Lump 90 is a semiconductor material with unique electronic properties, including high breakdown voltage and thermal conductivity, making it suitable for power electronics.

Q: Can Metallurgy Silicon Carbide /Sic Powder/Lump 90 be used in extreme environments?

A: Absolutely, SiC’s high temperature stability, resistance to radiation damage, and ability to withstand thermal shocks make it ideal for applications in space, nuclear reactors, and deep-well drilling.

Q: What gives Metallurgy Silicon Carbide /Sic Powder/Lump 90 its unique properties?

A: The covalent bond structure of Metallurgy Silicon Carbide /Sic Powder/Lump 90, along with its tight crystal lattice, contributes to its hardness, high melting point, and resistance to wear and corrosion.

Q: Is Metallurgy Silicon Carbide /Sic Powder/Lump 90 biocompatible?

A: SMetallurgy Silicon Carbide /Sic Powder/Lump 90 has been investigated for biomedical applications due to its biocompatibility, inertness, and durability, with potential uses in orthopedic implants and surgical instruments.

(Metallurgy Silicon Carbide /Sic Powder/Lump 90)