Overview of Made in Taiwan OEM/ODM CEB For Stainless Steel, Titanium Ball Nose Carbide end mill

Titanium Carbide (TiC) is a technical ceramic material renowned for its exceptional hardness, wear resistance, and high melting point. Composed of titanium and carbon atoms, it forms a part of the wider family of transition metal carbides. Its unique combination of properties makes it a versatile and valuable component in various industrial applications where extreme conditions necessitate robust and durable materials.

Features of Made in Taiwan OEM/ODM CEB For Stainless Steel, Titanium Ball Nose Carbide end mill

-

Exceptional Hardness: With a Vickers hardness ranging from 2000 to 3200 Hv, TiC ranks among the hardest materials, surpassing many steels and rivaling tungsten carbide.

-

High Melting Point: Boasting a melting point of approximately 3160°C, titanium carbide is ideal for high-temperature applications where stability and strength are crucial.

-

Oxidation Resistance: Forms a protective oxide layer at elevated temperatures, slowing down further oxidation and enhancing its performance in oxidative environments.

-

Chemical Stability: Resistant to most acids and alkalis, TiC maintains its integrity in corrosive conditions, excluding hydrofluoric acid and strong alkalis.

-

Thermal Conductivity: Exhibits good thermal conductivity, facilitating heat dissipation and enhancing performance in high-heat-load applications.

-

Density: Despite its hardness, titanium carbide has a relatively low density of about 4.93 g/cm³, contributing to its use in lightweight yet durable structures.

(Made in Taiwan OEM/ODM CEB For Stainless Steel, Titanium Ball Nose Carbide end mill)

Parameters of Made in Taiwan OEM/ODM CEB For Stainless Steel, Titanium Ball Nose Carbide end mill

The material you’ve mentioned is likely a combination of stainless steel and titanium, and it’s typically used for manufacturing components that require a high level of strength and durability. The type of metal you’re referring to may also depend on the specific use case or application you’re referring to.

In general, the parameters for such a CNC machine for stainless steel ball nose carbide end mill would include:

1. Input speed: The speed at which the material is input into the tool should be controlled according to the machine’s specifications. A high input speed can help ensure consistent output, while a low input speed can lead to precise measurements.

2. parameters: The blade diameter, length, and fineness of the blades will affect the effectiveness of the cutting process. with a wider blade diameter and longer life can cut through materials more easily, while a narrower blade diameter and shorter life can cause the material to become sharp.

3. Scribing parameters: Scribing is a crucial step in creating accurate end mill templates for your parts. You’ll need to specify the amount of guide stone required for each area being scribed, as well as any other necessary details such as chamfering or profile shaping.

4. Extraction parameters: Extracting refers to the process of removing the material from the end mill after it has been scribed. This parameter should take into account factors such as material properties (such as porosity or), location on the end mill, and the type of surface you want to work on.

5. Output pressure and distance: The pressure at which the material is being driven down the end mill will impact the shape and performance of your part. It should be controlled according to the machine’s operating specifications to ensure consistent results.

By following these parameters, you can create a CNC machine that meets the specific needs of your project and helps you produce high-quality parts efficiently and accurately.

(Made in Taiwan OEM/ODM CEB For Stainless Steel, Titanium Ball Nose Carbide end mill)

Applications of Made in Taiwan OEM/ODM CEB For Stainless Steel, Titanium Ball Nose Carbide end mill

-

Cutting Tools: Integrated into tool bits, inserts, and milling cutters due to its wear resistance and heat tolerance, enhancing tool life and machining efficiency.

-

Metalworking: As hardfacing coatings for dies, molds, and wear parts subjected to severe abrasive or erosive conditions.

-

Cemented Carbides: Mixed with other carbides and binders to form cemented carbide composites for drill bits, end mills, and other cutting tools.

-

Abrasive and Wear-Resistant Components: Used in pump parts, valve components, and seals where resistance to wear and corrosion is vital.

-

Military Armor: Incorporated into armor plating due to its hardness and lightweight properties, offering enhanced protection without adding excessive weight.

-

Chemical Processing Equipment: For parts that come into contact with corrosive chemicals, benefiting from TiC’s resistance to chemical attack.

Company Profile

MyCarbides is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality carbides and relative products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality carbide materials and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

FAQs of Made in Taiwan OEM/ODM CEB For Stainless Steel, Titanium Ball Nose Carbide end mill

Q: How is Made in Taiwan OEM/ODM CEB For Stainless Steel, Titanium Ball Nose Carbide end mill manufactured?

A: Made in Taiwan OEM/ODM CEB For Stainless Steel, Titanium Ball Nose Carbide end mill is typically produced through a process called carbothermal reduction, which involves reacting titanium dioxide with carbon at high temperatures.

Q: Is Made in Taiwan OEM/ODM CEB For Stainless Steel, Titanium Ball Nose Carbide end mill biocompatible?

A: While pure titanium is highly biocompatible, the biocompatibility of titanium carbide depends on the specific application and the potential release of titanium ions. Further testing is necessary for biomedical applications.

Q: How does Made in Taiwan OEM/ODM CEB For Stainless Steel, Titanium Ball Nose Carbide end mill compare to tungsten carbide in terms of hardness and toughness?

A: Both materials are hard, but tungsten carbide (WC) is slightly harder and tougher than titanium carbide, making WC more commonly used in tooling applications.

Q: Can Made in Taiwan OEM/ODM CEB For Stainless Steel, Titanium Ball Nose Carbide end mill be machined?

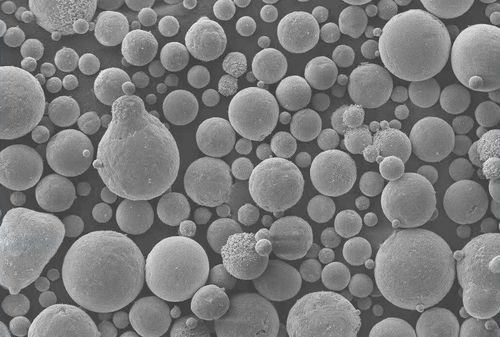

A: Due to its extreme hardness, traditional machining methods are challenging. Instead, TiC components are often formed through powder metallurgy, sintering, or by applying coatings via thermal spray or Physical Vapor Deposition (PVD).

Q: What are the main advantages of using Made in Taiwan OEM/ODM CEB For Stainless Steel, Titanium Ball Nose Carbide end mill in cutting tools?

A: TiC enhances tool life, allows for higher cutting speeds, and improves wear resistance, especially in applications involving high temperatures or abrasive materials.

(Made in Taiwan OEM/ODM CEB For Stainless Steel, Titanium Ball Nose Carbide end mill)