Overview of XXX

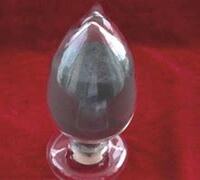

Zirconium Carbide (ZrC) is an extremely hard and refractory ceramic material composed of zirconium and carbon atoms. It belongs to the family of transition metal carbides, known for their high melting points, exceptional hardness, and impressive chemical stability. Zirconium carbide offers unique properties that make it suitable for demanding environments where high temperatures, wear resistance, and corrosion are significant concerns.

Features of high quality Abrasive Flap Disc of Zirconium polishing stainless steel, metal,wood, stone

-

High Melting Point: Zirconium carbide has an incredibly high melting point of approximately 3530°C, making it one of the most heat-resistant materials.

-

Exceptional Hardness: With a Vickers hardness rating around 2200 Hv, ZrC is harder than most steels and many other ceramic materials, providing excellent wear resistance.

-

Oxidation Resistance: Forms a protective oxide layer when exposed to oxygen, which prevents further oxidation, enhancing its high-temperature performance.

-

Chemical Stability: Resistant to most acids, except for hydrofluoric acid, and shows excellent resistance to corrosion from alkalis and salt solutions.

-

Thermal Conductivity: Exhibits good thermal conductivity, which aids in heat dissipation and is beneficial for applications involving high heat loads.

-

Nuclear Application Suitability: Zirconium carbide’s low neutron absorption cross-section makes it attractive for use in nuclear reactor components.

(high quality Abrasive Flap Disc of Zirconium polishing stainless steel, metal,wood, stone)

Parameters of high quality Abrasive Flap Disc of Zirconium polishing stainless steel, metal,wood, stone

The specific characteristics of high-quality abrasive flaps discs can vary depending on the material they are used for, such as stainless steel, metal, wood, or stone. However, some common parameters that may be relevant include:

* Size: The size of the abrasive disc is an important factor in determining its effectiveness. Generally speaking, larger disks are more effective at removing tough scratches and imperfections.

* Material: Different materials require different types of abrasive compounds to achieve optimal results. For example, abrasive wheels made from carbon or glass may work better for cutting metals, while sandpaper made from silicon carbide may be better for sanding wooden surfaces.

* Abrasive content: The amount of abrasive material on the flaps disc determines its ability to remove scratches and other imperfections. A higher percentage of abrasive material will result in a greater removal rate, but it will also create more dust and potentially damage the surface being polished.

* Efficiency: The efficiency of the flaps disc depends on its speed and power output. A higher-powered disc with a large flapping area will typically generate more force than a smaller, less powerful disc.

* Durability: High-quality abrasive flaps discs should be durable and able to withstand repeated use without breaking or wearing down quickly. This may require careful selection and storage to ensure the best possible performance.

Overall, selecting the right type of abrasive flaps disc for a particular task will depend on factors such as the material being worked on, the desired level of effectiveness, and personal preferences for speed and power output. It may be helpful to do some research and experimentation to determine which type of flaps disc works best for your specific application.

(high quality Abrasive Flap Disc of Zirconium polishing stainless steel, metal,wood, stone)

Applications of high quality Abrasive Flap Disc of Zirconium polishing stainless steel, metal,wood, stone

-

Nuclear Industry: Used in fuel element cladding, control rods, and other reactor core components due to its high-temperature stability and low neutron absorption.

-

Ceramic Cutting Tools: Incorporated into cutting tool materials to enhance their wear resistance and performance in machining hard materials.

-

Heat Exchangers and Furnace Components: Ideal for high-temperature applications due to its thermal stability and corrosion resistance.

-

Wear-Resistant Coatings: Applied as coatings on metal parts subject to severe wear or erosion, such as pump impellers and valve components.

-

Aerospace: In high-temperature and high-stress applications within jet engines and spacecraft due to its thermal and mechanical properties.

-

Chemical Processing Equipment: Components in contact with corrosive chemicals where resistance to both wear and chemical attack is crucial.

Company Profile

MyCarbides is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality carbides and relative products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality carbide materials and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

FAQs of high quality Abrasive Flap Disc of Zirconium polishing stainless steel, metal,wood, stone

Q: How is high quality Abrasive Flap Disc of Zirconium polishing stainless steel, metal,wood, stone produced?

A: high quality Abrasive Flap Disc of Zirconium polishing stainless steel, metal,wood, stone is typically synthesized through carbothermal reduction of zirconium dioxide (ZrO2) with carbon at very high temperatures.

Q: Is high quality Abrasive Flap Disc of Zirconium polishing stainless steel, metal,wood, stone biocompatible?

A: While zirconium itself has good biocompatibility, specific studies are needed to determine the biocompatibility of zirconium carbide for medical applications.

Q: How does high quality Abrasive Flap Disc of Zirconium polishing stainless steel, metal,wood, stone compare to tungsten carbide in terms of hardness and thermal properties?

A: Tungsten carbide (WC) is slightly harder than zirconium carbide and has a higher melting point, making WC more commonly used for applications requiring extreme hardness and heat resistance.

Q: Can high quality Abrasive Flap Disc of Zirconium polishing stainless steel, metal,wood, stone be machined or shaped easily?

A: Due to its extreme hardness, zirconium carbide is challenging to machine using conventional methods. It is typically formed through powder metallurgy techniques, sintering, or used as a coating applied by thermal spray or CVD/PECVD processes.

Q: What is the main advantage of using high quality Abrasive Flap Disc of Zirconium polishing stainless steel, metal,wood, stone in nuclear applications?

A: Its low neutron absorption cross-section and high-temperature stability make it an ideal material for components in nuclear reactors, minimizing interference with nuclear reactions while maintaining integrity under extreme conditions.

(high quality Abrasive Flap Disc of Zirconium polishing stainless steel, metal,wood, stone)