Title: “Tungsten carbide:”

(How To Test Tungsten Carbide To Tell If Its Really Tungsten Carbide?)

As the world is becoming increasingly aware of the dangers of hazardous materials like metals like tungsten carbide (WCB), it’s crucial to understand how to test their true performance before using them in any industry. One way to do this is by utilizing the process known as casting a test mold.

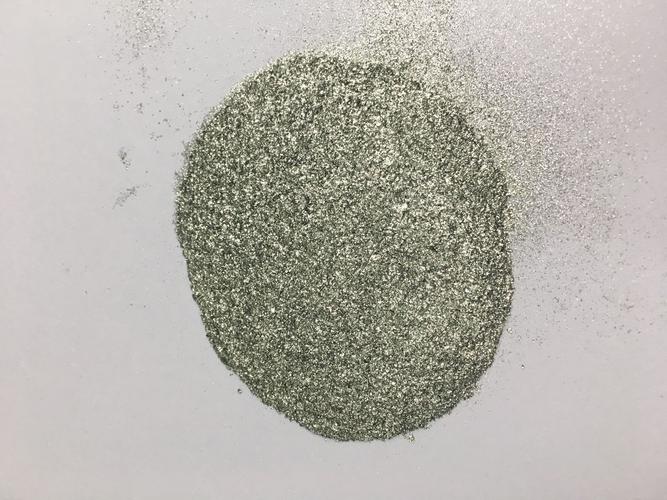

## Preparing a Sample

To conduct a test mold, you will need to prepare a sample of tungsten carbide that meets the specific requirements of your application. This can be done through a variety of methods, depending on the type of tungsten carbide being used. For example, in the case of WCB, you may want to use a carbon equivalent melt (CEM) made from iron-based compounds such as Fe3O4 or Ni3O4. Alternatively, you may opt for a pure metallic tungsten carbide that is prepared in a conventional melt, such as aluminum or steel.

## Making a casting mold

Once you have prepared your sample, you can start casting a casting mold using a high-speed roller press or mechanical injection molding. You should follow the manufacturer’s instructions carefully to ensure that the mold is precise and has no flaws.

The casting process involves shaping the material into the desired shape, applying pressure to bind it together, and then cooling it to complete the job. The resulting mold should display a consistent consistency and resistance to various applications, including wettable corrosion and heat transfer. You can check the surface finish of the mold to verify that it meets the expected specifications.

## Testing the Material

After completing the casting mold, you can begin testing the material to determine its true performance. Here are some key tests that you should perform:

– Porosity: A tool that measures the amount of space inside a material is useful for determining its porosity. The higher the porosity, the more space it allows for flow and movement.

– Fillability: This measure the amount of concrete that a material can fill without overflowing. A higher fillability indicates better compression strength and durability.

– Specificity: How well does the material adhere to the surface of the mold? A higher degree of specificity means better compatibility with different types of surfaces and applications.

– Erosion rate: What is the rate at which the material can be affected by water, air, or other substances?

By conducting these tests, you can gain valuable insights into the actual properties ofWCB and make informed decisions about its application. Remember to always read the manufacturer’s documentation thoroughly before using any new material to prevent errors and potential safety hazards.

## Conclusion

(How To Test Tungsten Carbide To Tell If Its Really Tungsten Carbide?)

Understanding the benefits of testing WCB’s performance can help you identify any issues with the material and make more informed decisions about its usage. By preparing a correct casting mold and conducting rigorous testing, you can ensure that wcb meets all the necessary standards and meets the highest quality standards.