Sintered carbide tools are highly valued tools used in various industries for precise cutting, drilling, and grinding tasks. The process of manufacturing sintered carbide tools involves several stages that ensure their optimal performance and reliability.

(How Are Sintered Carbide Tools Manufactured?)

The first stage is the preparation of the workpiece. This involves cleaning and the surface to remove any rough edges or defects that may affect the tool’s performance. The surface of the workpiece is then coated with a ceramic material called zirconia, which provides excellent wear resistance and improves the accuracy of the cut.

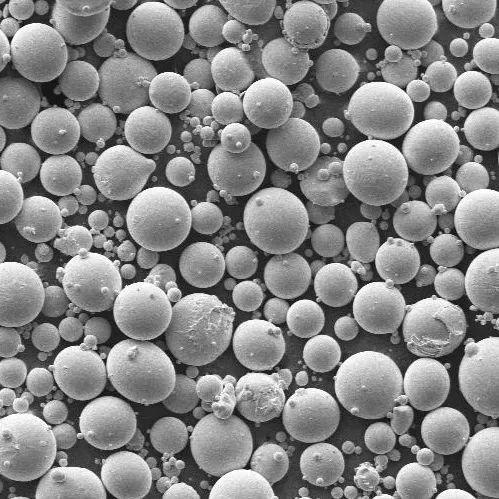

Once the workpiece is properly prepared, the next step is the sintering process. During this stage, the carbide particles are heated to extremely high temperatures, causing them to bond together and form a solid matrix. The temperature range for sintering varies depending on the type of tool, but it typically ranges from 1200°C to 1800°C. Once the tool has been sintered, it is ready for use.

The sintering process also involves the formation of additional protective coatings, such as wear-resistant coatings and heat-resistant coatings. These coatings help to protect the tool from corrosion, wear, and tear, ensuring its long-term usefulness.

Finally, after sintering, the tool undergoes a heat treatment process, which helps to strengthen the bonds between the carbide particles and improve their overall performance. The heat treatment process typically involves heating the tool to lower temperatures for a specific period of time, followed by rapid cooling to room temperature. This process helps to create a uniform layer of carbide on the tool, improving its wear resistance and durability.

(How Are Sintered Carbide Tools Manufactured?)

In conclusion, sintered carbide tools are highly valued tools used in various industries for precise cutting, drilling, and grinding tasks. The manufacturing process involves several stages that ensure their optimal performance and reliability. From preparing the workpiece to sintering the tool, these stages involve careful planning and execution to ensure the creation of a high-quality, durable tool that meets the needs of users.