“Chasing the Future: The Potential of Resizing Tungsten Carbide”

(Can Tungsten Carbide Be Resized?)

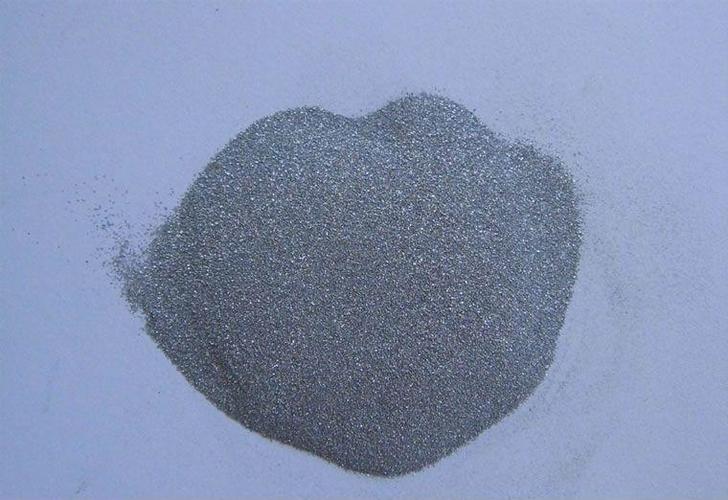

Tungsten carbide is an incredibly versatile material that has been around for centuries, but its potential for resizeability holds great promise. In this blog post, we’ll explore the fascinating world of tungsten carbide resizing, delve into its historical context, and discover some of the latest advancements in this exciting field.

Historically, tungsten carbide was primarily used as a hardening agent in manufacturing processes. However, over time, it began to be recognized as a versatile material that could be resized by heating or cooling it under controlled conditions. This led to the development of various types of tungsten carbide resizing techniques, including physical methods like cutting and grinding, and chemical methods like heat treatment and acid etching.

One of the most promising applications of tungsten carbide resizing is in the production of medical devices. For example, doctors can use special instruments called dancers’ shoes to create customized orthotics for patients with foot problems. These custom orthotics can then be resized to fit each individual patient’s specific needs, ensuring maximum comfort and effectiveness.

In addition to medical applications, tungsten carbide resizing has also found use in industries such as aerospace and automotive. Engineers can use specialized tools to create customized components that can be resized to meet changing requirements. For example, in aerospace, engineers can create parts that can be resized to fit different engine designs, increasing the overall performance of the aircraft.

As we move forward in the realm of tungsten carbide resizing, we can expect to see even more innovative applications. Researchers are exploring new materials and techniques to enhance the versatility of tungsten carbide, making it even more capable of resizing to meet changing needs. Additionally, there are ongoing efforts to develop new resizers that can improve the efficiency and accuracy of the resizing process.

Despite its incredible potential, there are still many challenges that need to be overcome before tungsten carbide resizing becomes a reality on a larger scale. For example, achieving precise control over the resizing process can be difficult, particularly when working with complex geometries. Additionally, researchers must carefully consider the environmental impact of resizing, as any changes to the size of a part could have unintended consequences.

(Can Tungsten Carbide Be Resized?)

Overall, tungsten carbide resizing represents a exciting opportunity for researchers and industry professionals alike. With continued advances in technology and the development of new materials, we can expect to see more and more applications of this versatile material in the future. Whether you’re interested in the medical field, aerospace engineering, or simply tinkering with unique parts, there is no denying that tungsten carbide resizing offers endless possibilities for creativity and innovation. So what are you waiting for? Get out there and start resizing – the future is calling!

Inquiry us

if you want to want to know more, please feel free to contact us. (nanotrun@yahoo.com)