Title: What is the Secret to Reaching Your?

(Are Carbide Tools Harder Than Ceramic)

New Title: Carbide Tools vs. Ceramic Tools – The Key Differences in Their Performance

In this blog post, we will explore the key differences between carbide tools and ceramic tools, which can help you determine if your project requires them.

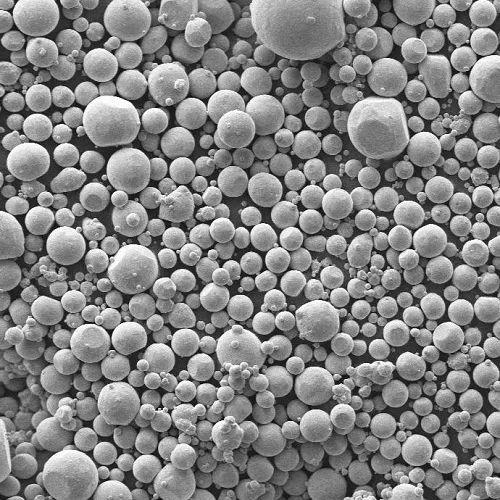

carbide tools are made of materials that contain small pieces of carbonized (CNC). These tools are commonly used in metal fabrication, metal grinding, and more, and they are designed for precise cutting and deburring applications. However, their strength is relatively weak compared to ceramic tools, which are formed from a mixture of glass, sand, and other materials. This makes them better suited for tasks such as honing and honing surfaces, while ceramic tools have a higher strength and durability.

On the other hand, ceramic tools are typically made from a combination of glass, sand, and other materials, which can be into hard, durable forms. They are often used in automotive applications, where they are used to create structural elements and surfaces. Additionally, ceramic tools tend to have a lower weight than carbide tools, making them ideal for heavy projects that require a lot of force and precision.

The main difference between carbide tools and ceramic tools is their size and shape. Carbide tools are generally smaller and more compact than ceramic tools, which are larger and more substantial. This means that caribide tools may be better suited for smaller, simpler tasks, while ceramic tools may be better suited for larger, more complex tasks.

Another important difference is their cost. While carbide tools can be more expensive than ceramic tools due to their high cost of materials, they tend to be slightly less expensive overall. In contrast, ceramic tools are generally less expensive than carbide tools due to their lower cost of materials.

(Are Carbide Tools Harder Than Ceramic)

In conclusion, the choice between carbide tools and ceramic tools ultimately depends on the specific application and task at hand. If you need to perform precise cuts or grind metal surfaces, carbide tools may be the best option. However, if you need a larger, more complex tool that can withstand pressure and strength, ceramic tools may be a better choice. By considering the size, shape, and cost of each tool, you can make an informed decision and choose the right tool for your project.