Title: “Two Carbides, One Powerhouse: The Secret Superheroes of Modern Engineering”

(Dual Advantage: Assessing the Benefits of Dual Carbides)

Imagine a world where materials don’t just survive harsh conditions—they laugh in the face of them. Meet dual carbides, the dynamic duo of the engineering universe. These aren’t your average metals; they’re like the Batman and Robin of industrial materials, teaming up to deliver twice the toughness, twice the resilience, and twice the swagger. Let’s dive into why these unsung heroes are quietly revolutionizing everything from your smartphone to spacecraft.

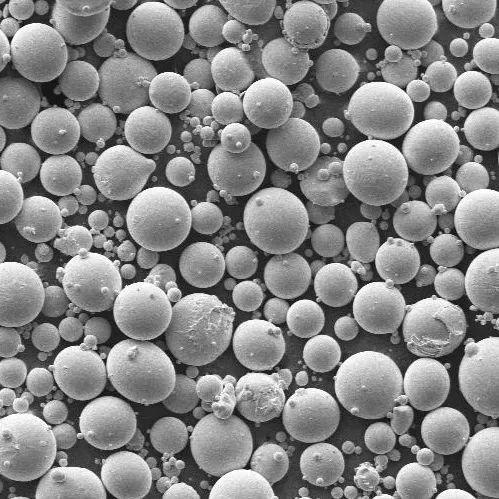

First off, what even are carbides? Think of them as the tough guys of the material world—compounds where carbon buddies up with a metal or ceramic, creating something harder than a diamond-tipped drill. But when you pair two carbides together? Magic happens. Dual carbides combine the best traits of their parents, like a supercharged alloy on steroids. Imagine a material that’s both harder than your ex’s heart and more heat-resistant than a dragon’s breath. That’s dual carbides for you.

Take cutting tools, for example. A regular drill bit might tap out after gnawing through a few layers of steel. But slap some dual carbide coating on that bad boy, and suddenly it’s slicing through metal like a hot knife through butter—even after hours of abuse. Why? Because dual carbides laugh at friction. Their layered structure disperses heat and stress, meaning tools last longer, work faster, and save companies a fortune in replacements. It’s like giving machinery an infinite-life cheat code.

But wait, there’s more! Dual carbides aren’t just for heavy-duty industrial gigs. They’re sneaking into everyday tech, too. Your phone’s sleek, scratch-resistant casing? Thank dual carbides. The tiny, ultra-durable components in your smartwatch? Yep, same heroes. Even renewable energy tech, like wind turbines and solar panels, relies on these materials to withstand decades of punishment from Mother Nature. They’re the silent guardians keeping your gadgets intact and your green energy flowing.

Now, let’s talk aerospace—the ultimate proving ground for materials. Jet engines operate at temperatures that would melt most metals into puddles. But dual carbides? They thrive in the inferno. By layering different carbide compositions, engineers create parts that resist oxidation, erosion, and thermal shock. This isn’t just about durability; it’s about safety. When a plane’s engine can handle extreme stress without cracking, your mid-flight nap stays blissfully uninterrupted.

Here’s the kicker: dual carbides are eco-friendly rockstars. Longer-lasting materials mean fewer replacements, less waste, and lower carbon footprints. Factories using dual carbide-coated tools reduce energy consumption because they’re not constantly halting production to swap out worn parts. It’s a win-win—companies save money, and the planet gets a breather. Who knew saving the world could be so metal?

But let’s not ignore the cool factor. Scientists are now tweaking dual carbide recipes like master chefs, experimenting with nano-layers and exotic element combos. The goal? Materials that self-heal, adapt to stress, or even harvest energy. Picture a bridge that repairs its own cracks or a phone battery that never dies. With dual carbides, these sci-fi dreams are inching toward reality.

(Dual Advantage: Assessing the Benefits of Dual Carbides)

In a nutshell, dual carbides are the ultimate wingmen for progress. They’re tough, versatile, and quietly powering the tech that shapes our lives. So next time you marvel at a skyscraper, charge your phone, or board a plane, remember: somewhere in the mix, there’s a duo of carbides working overtime. They might not wear capes, but they’re definitely saving the day—one molecule at a time.

Inquiry us

if you want to want to know more, please feel free to contact us. (nanotrun@yahoo.com)