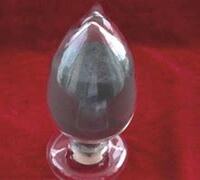

Overview of CAS 12069-32-8 Boron carbide B4C 325mesh Purity 94 95% boron carbide for refractory

Boron Carbide (B4C) is a ceramic compound renowned for its exceptional hardness and wear resistance, ranking just below diamond and cubic boron nitride in terms of hardness. Composed of boron and carbon atoms arranged in a covalently bonded crystal structure, it exhibits unique physical and chemical properties that make it highly valuable in various industrial and military applications. Boron carbide’s high melting point, low density, neutron-absorbing capability, and extreme toughness further distinguish it among advanced materials.

Features of CAS 12069-32-8 Boron carbide B4C 325mesh Purity 94 95% boron carbide for refractory

-

Extreme Hardness: With a Mohs hardness of around 9.3 to 9.5, boron carbide is one of the hardest materials known, surpassed only by diamond and cubic boron nitride.

-

Lightweight: Despite its hardness, boron carbide has a relatively low density of about 2.52 g/cm³, which makes it an attractive material for lightweight armor systems.

-

Thermal Stability: It possesses excellent thermal stability, maintaining its properties up to temperatures around 2,000°C, making it suitable for high-temperature applications.

-

Neutron Absorption: Boron carbide is a potent neutron absorber due to its boron content, making it ideal for nuclear shielding and control rods.

-

Chemical Resistance: Resistant to most acids and alkalis, except for hydrofluoric acid and hot concentrated alkaline solutions, ensuring durability in corrosive environments.

-

Abrasion Resistance: Its exceptional wear resistance makes it suitable for applications where friction and abrasion are prevalent, such as sandblasting nozzles.

(CAS 12069-32-8 Boron carbide B4C 325mesh Purity 94 95% boron carbide for refractory)

Parameters of CAS 12069-32-8 Boron carbide B4C 325mesh Purity 94 95% boron carbide for refractory

Cas 12069-32-8 Boron carbide B4C 325 mesh Purity 94 is an indicator that measures the purity of boron carbide (B4C) 325 mesh in a laboratory setting. This specification is commonly used to determine the level of concentration of Boron in a particular mixture.

The Boron carbide B4C 325 mesh is made from boron carbide powder and has a particle size of 325 mesh. The Purity 94 parameter refers to the level of pure Boron in this specific sample. It indicates how much pure Boron is present relative to the total amount of boron in the sample.

In general, the higher the Purity 94 parameter, the more pure Boron is in the sample. However, it’s important to note that Purity 94 may not always accurately reflect the actual level of purity of Boron in the sample. Other factors such as the composition of the sample, its processing conditions, and the presence of impurities can also impact the level of purity.

To ensure accurate Purity 94 measurement, it’s recommended to use a well-controlled batch of Boron carbide B4C 325 mesh under a controlled environment. This includes maintaining constant temperature, pressure, and humidity levels throughout the batch process. The samples should also be tested in an oven at the appropriate temperature to remove any contaminants before being used for further analysis.

Overall, Cas 12069-32-8 Boron carbide B4C 325 mesh provides valuable information about the purity of Boron in a given sample. By using this indicator in conjunction with other testing methods, scientists can gain a comprehensive understanding of the Boron content of a given material and make informed decisions about the application of boron in various industries.

(CAS 12069-32-8 Boron carbide B4C 325mesh Purity 94 95% boron carbide for refractory)

Applications of CAS 12069-32-8 Boron carbide B4C 325mesh Purity 94 95% boron carbide for refractory

-

Armor Systems: Widely used in body armor, vehicle armor, and bulletproof vests due to its lightweight and superior protection capabilities.

-

Nuclear Applications: As control rods and shielding material in nuclear reactors because of its neutron absorbing properties.

-

Abrasive and Cutting Tools: In grinding wheels, polishing powders, and cutting tools due to its hardness and wear resistance.

-

Industrial Nozzles: For sandblasting and water jet cutting applications where resistance to wear and erosion is critical.

-

Military and Defense: As a component in armor-piercing projectiles and defensive systems.

Company Profile

MyCarbides is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality carbides and relative products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality carbide materials and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

FAQs of CAS 12069-32-8 Boron carbide B4C 325mesh Purity 94 95% boron carbide for refractory

Q: Is CAS 12069-32-8 Boron carbide B4C 325mesh Purity 94 95% boron carbide for refractory toxic?

A: Pure boron carbide is generally considered safe to handle. However, during machining or grinding, dust inhalation can be a concern, requiring proper ventilation and protective equipment.

Q: Can CAS 12069-32-8 Boron carbide B4C 325mesh Purity 94 95% boron carbide for refractory be machined?

A: Due to its extreme hardness, machining boron carbide is difficult and requires specialized techniques and diamond tooling. Grinding, EDM (Electrical Discharge Machining), or laser cutting are common methods.

Q: How does CAS 12069-32-8 Boron carbide B4C 325mesh Purity 94 95% boron carbide for refractory compare to tungsten carbide in terms of hardness?

A: CAS 12069-32-8 Boron carbide B4C 325mesh Purity 94 95% boron carbide for refractory is harder than tungsten carbide, with a Mohs hardness of around 9.3 to 9.5 compared to tungsten carbide’s 8.5 to 9.

Q: What is the primary use of CAS 12069-32-8 Boron carbide B4C 325mesh Purity 94 95% boron carbide for refractory in the military sector?

A: CAS 12069-32-8 Boron carbide B4C 325mesh Purity 94 95% boron carbide for refractory is primarily used in the military for body armor, armored vehicles, and as a component in armor-piercing ammunition due to its combination of hardness, light weight, and ballistic performance.

Q: Can CAS 12069-32-8 Boron carbide B4C 325mesh Purity 94 95% boron carbide for refractory be used in high-temperature applications?

A: Yes, CAS 12069-32-8 Boron carbide B4C 325mesh Purity 94 95% boron carbide for refractory maintains its structural integrity and properties up to very high temperatures, making it suitable for use in extreme heat environments such as furnace linings and high-temperature ceramics.

(CAS 12069-32-8 Boron carbide B4C 325mesh Purity 94 95% boron carbide for refractory)