Title: How much R carbide tips for saws

(How Much R Carbide Tips For Saws)

Introduction:

Casting iron and carbide tools can be some of the most powerful and versatile tools available in the shop. One of the key factors that determine the quality of a carbide tool is the size and shape of the carbide tip. Carbide tips come in different sizes, shapes, and grades to meet the needs of various applications.

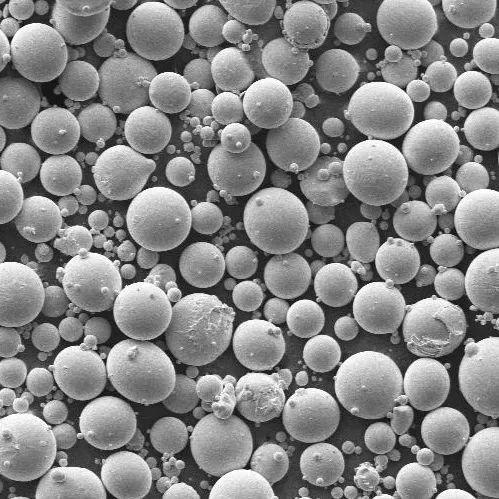

Choosing the right size and shape of carbide tip is important as it affects the tool’s performance and efficiency. Carbide tips have two main types: spherical and channel-shaped. Spherical tips are flat and have a uniform grain profile throughout, while channel-shaped tips have a series of channels running through the center of the tip.

The shape of the carbide tip also plays a role in its wear rate. Spherical tips tend to have a higher wear rate than channel-shaped tips because they create more friction between the tool and the workpiece. Channel-shaped tips, on the other hand, have a lower wear rate because they create less friction.

In addition to the size and shape of the carbide tip, the grade of the carbide also matters. Grade A carbide has a harder and smoother finish, making it ideal for cutting hard materials like metal. Grade B carbide has a softer finish, but it is still suitable for cutting most types of material. Grade C carbide is the least durable and is not recommended for use with demanding tasks.

When choosing carbide tips for your saw, it is essential to consider the size and shape of the tool, as well as the intended application. Spherical tips are often used for drilling and circular saws, while channel-shaped tips are commonly used for miter saws and circular saws.

(How Much R Carbide Tips For Saws)

In conclusion, choosing the right size and shape of carbide tips is crucial for achieving optimal performance and efficiency from your saws. By taking into account the size and shape of the tool, as well as the intended application, you can select the best carbide tips for your saws. With the right carbide tips, you can achieve accurate cuts, consistent results, and high productivity.