Overview of XXX

Zirconium Carbide (ZrC) is an extremely hard and refractory ceramic material composed of zirconium and carbon atoms. It belongs to the family of transition metal carbides, known for their high melting points, exceptional hardness, and impressive chemical stability. Zirconium carbide offers unique properties that make it suitable for demanding environments where high temperatures, wear resistance, and corrosion are significant concerns.

Features of 100-180mm blue Zirconium Oxide Fiber Sanding Disc

-

High Melting Point: Zirconium carbide has an incredibly high melting point of approximately 3530°C, making it one of the most heat-resistant materials.

-

Exceptional Hardness: With a Vickers hardness rating around 2200 Hv, ZrC is harder than most steels and many other ceramic materials, providing excellent wear resistance.

-

Oxidation Resistance: Forms a protective oxide layer when exposed to oxygen, which prevents further oxidation, enhancing its high-temperature performance.

-

Chemical Stability: Resistant to most acids, except for hydrofluoric acid, and shows excellent resistance to corrosion from alkalis and salt solutions.

-

Thermal Conductivity: Exhibits good thermal conductivity, which aids in heat dissipation and is beneficial for applications involving high heat loads.

-

Nuclear Application Suitability: Zirconium carbide’s low neutron absorption cross-section makes it attractive for use in nuclear reactor components.

(100-180mm blue Zirconium Oxide Fiber Sanding Disc)

Parameters of 100-180mm blue Zirconium Oxide Fiber Sanding Disc

The parameter for 100-180mm blue Zirconium oxide fiber sanding disc may vary depending on the specific product and manufacturer, but generally it can be determined by looking at the label or documentation provided with the disc.

The wavelength of light used to cure the Zirconium oxide fiber is typically between 450 nm and 630 nm, which corresponds to the blue portion of the visible spectrum. The Zirconium oxide fiber itself is typically used as a sanding medium in various applications such as cutting and polishing, and its size and roughness can affect the performance of the sanding process.

In general, higher frequency waves tend to result in faster sanding speeds and smoother surfaces, while lower frequency waves can produce more aggressive rounding and reduce surface finish. Therefore, choosing the appropriate wavelength for the sanding process depends on the specific requirements of the application and the desired end result.

(100-180mm blue Zirconium Oxide Fiber Sanding Disc)

Applications of 100-180mm blue Zirconium Oxide Fiber Sanding Disc

-

Nuclear Industry: Used in fuel element cladding, control rods, and other reactor core components due to its high-temperature stability and low neutron absorption.

-

Ceramic Cutting Tools: Incorporated into cutting tool materials to enhance their wear resistance and performance in machining hard materials.

-

Heat Exchangers and Furnace Components: Ideal for high-temperature applications due to its thermal stability and corrosion resistance.

-

Wear-Resistant Coatings: Applied as coatings on metal parts subject to severe wear or erosion, such as pump impellers and valve components.

-

Aerospace: In high-temperature and high-stress applications within jet engines and spacecraft due to its thermal and mechanical properties.

-

Chemical Processing Equipment: Components in contact with corrosive chemicals where resistance to both wear and chemical attack is crucial.

Company Profile

MyCarbides is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality carbides and relative products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality carbide materials and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

FAQs of 100-180mm blue Zirconium Oxide Fiber Sanding Disc

Q: How is 100-180mm blue Zirconium Oxide Fiber Sanding Disc produced?

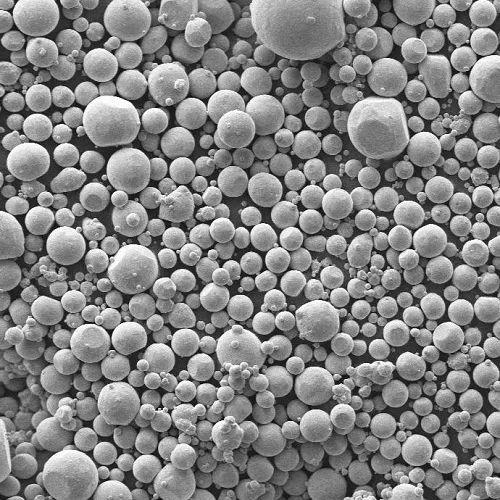

A: 100-180mm blue Zirconium Oxide Fiber Sanding Disc is typically synthesized through carbothermal reduction of zirconium dioxide (ZrO2) with carbon at very high temperatures.

Q: Is 100-180mm blue Zirconium Oxide Fiber Sanding Disc biocompatible?

A: While zirconium itself has good biocompatibility, specific studies are needed to determine the biocompatibility of zirconium carbide for medical applications.

Q: How does 100-180mm blue Zirconium Oxide Fiber Sanding Disc compare to tungsten carbide in terms of hardness and thermal properties?

A: Tungsten carbide (WC) is slightly harder than zirconium carbide and has a higher melting point, making WC more commonly used for applications requiring extreme hardness and heat resistance.

Q: Can 100-180mm blue Zirconium Oxide Fiber Sanding Disc be machined or shaped easily?

A: Due to its extreme hardness, zirconium carbide is challenging to machine using conventional methods. It is typically formed through powder metallurgy techniques, sintering, or used as a coating applied by thermal spray or CVD/PECVD processes.

Q: What is the main advantage of using 100-180mm blue Zirconium Oxide Fiber Sanding Disc in nuclear applications?

A: Its low neutron absorption cross-section and high-temperature stability make it an ideal material for components in nuclear reactors, minimizing interference with nuclear reactions while maintaining integrity under extreme conditions.

(100-180mm blue Zirconium Oxide Fiber Sanding Disc)