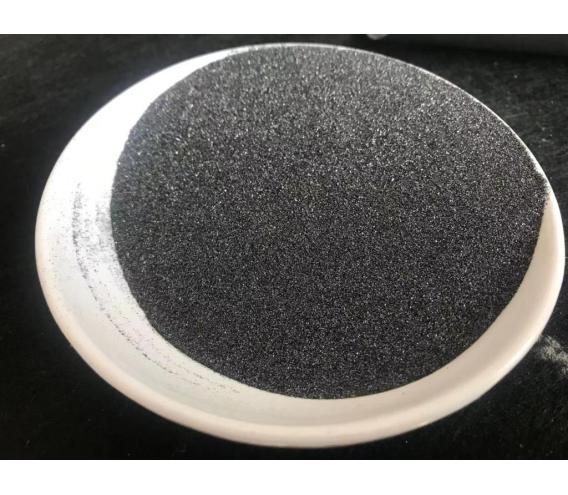

Overview of Compound Carbide Powder 90Ta 10Nb 90/10 Tantalum Carbide/Niobium Carbide

Niobium Carbide (NbC) is a refractory ceramic compound composed of niobium and carbon elements, known for its exceptional hardness, high melting point, and excellent thermal and electrical conductivity. It belongs to the family of transition metal carbides, which are valued for their remarkable mechanical properties and resistance to extreme environments. Niobium carbide is a dark gray, extremely hard material that finds application in areas requiring wear resistance, high-temperature stability, and corrosion resistance.

Features of Compound Carbide Powder 90Ta 10Nb 90/10 Tantalum Carbide/Niobium Carbide

-

High Melting Point: Niobium carbide has a melting point of approximately 3,400 to 3,500°C, making it suitable for high-temperature applications.

-

Hardness and Wear Resistance: With a Vickers hardness in the range of 2000-2500 Hv, NbC is one of the hardest materials, providing excellent wear resistance in abrasive environments.

-

Thermal Conductivity: It exhibits good thermal conductivity, facilitating heat dissipation and making it useful in high-heat-load applications.

-

Chemical Stability: Niobium carbide is resistant to corrosion from most acids and alkalis, excluding hydrofluoric acid, and is stable under oxidizing conditions.

-

Electrical Conductivity: Although a ceramic, niobium carbide demonstrates moderate electrical conductivity, contributing to its use in some electronic applications.

-

Density: Despite its hardness, niobium carbide has a relatively high density of about 8.53 g/cm³, adding to its mass efficiency in wear-resistant coatings.

(Compound Carbide Powder 90Ta 10Nb 90/10 Tantalum Carbide/Niobium Carbide)

Parameters of Compound Carbide Powder 90Ta 10Nb 90/10 Tantalum Carbide/Niobium Carbide

The compound carbide powder you are referring to is a mixture of 90 Ta, 10 Nb, and 90/10 Ta-Nb composite particles. The ta-numbers refer to the atomic numbers of the metal ions present in the mixture.

The “Ta” number represents Ta (Tungsten) which is an element with the atomic number 42, and the “Nb” number represents Nb (Neville) which is an element with the atomic number 86.

The “90/10” notation refers to the ratio of Ta to Nb in the mixture. In this case, it means that the Ta content is 90% and the Nb content is 10%.

This compound carbide powder has several advantages over other types of carbides, including higher strength and wear resistance due to its balanced Ta and Nb contents, improved melting point due to its Ta-rich composition, and enhanced hardness and durability due to its high Ta content. It is commonly used in industries such as aerospace, automotive, and manufacturing for various applications where high strength and wear resistance are required.

(Compound Carbide Powder 90Ta 10Nb 90/10 Tantalum Carbide/Niobium Carbide)

Applications of Compound Carbide Powder 90Ta 10Nb 90/10 Tantalum Carbide/Niobium Carbide

-

Cutting Tools and Tool Inserts: In the manufacturing of cutting and machining tools due to its wear resistance and ability to maintain sharp edges at high temperatures.

-

Wear-Resistant Coatings: As a coating on metal parts exposed to severe wear conditions, such as drill bits, mining equipment, and pump components.

-

Heat Shields and Furnace Components: In high-temperature furnaces and kilns due to its excellent thermal stability and resistance to oxidation.

-

Electrode Materials: In some specialized electrodes for electrical discharge machining (EDM) and electrochemical processes.

-

Cemented Carbides: As a component in cemented carbide composites, enhancing their toughness and wear resistance.

Company Profile

MyCarbides is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality carbides and relative products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality carbide materials and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

FAQs of Compound Carbide Powder 90Ta 10Nb 90/10 Tantalum Carbide/Niobium Carbide

Q: How is Compound Carbide Powder 90Ta 10Nb 90/10 Tantalum Carbide/Niobium Carbide produced?

A: Compound Carbide Powder 90Ta 10Nb 90/10 Tantalum Carbide/Niobium Carbide is typically synthesized through the carburization of niobium metal powder or oxide at high temperatures in a reducing atmosphere or via direct reaction of niobium with carbon.

Q: Can Compound Carbide Powder 90Ta 10Nb 90/10 Tantalum Carbide/Niobium Carbide be machined?

A: Due to its extreme hardness, machining niobium carbide directly is challenging. It is often fabricated using powder metallurgy techniques, sintering, or applied as a coating through processes like chemical vapor deposition (CVD) or physical vapor deposition (PVD).

Q: Is Compound Carbide Powder 90Ta 10Nb 90/10 Tantalum Carbide/Niobium Carbide biocompatible?

A: While not extensively studied for biomedical applications, niobium-based materials generally exhibit good biocompatibility. Specific studies would be required to assess NbC’s suitability for biomedical implants.

Q: How does Compound Carbide Powder 90Ta 10Nb 90/10 Tantalum Carbide/Niobium Carbide compare to tungsten carbide in terms of hardness?

A: Both are hard materials, but tungsten carbide (WC) is slightly harder, with a typical Vickers hardness of around 2200 Hv, whereas niobium carbide ranges from 2000 to 2500 Hv.

Q: What are the main advantages of using Compound Carbide Powder 90Ta 10Nb 90/10 Tantalum Carbide/Niobium Carbide in tooling applications?

A: The advantages include increased tool life due to high hardness and wear resistance, improved heat resistance allowing for faster machining speeds, and retention of cutting edge sharpness even under high loads.

(Compound Carbide Powder 90Ta 10Nb 90/10 Tantalum Carbide/Niobium Carbide)