Title: How to Sharpen Carbide scraper blades

(how to sharpen carbide scraper blade)

A carbide scraper blade is an essential tool for cleaning, smoothing and removing loose dust or debris from surfaces such as tables, countertops, and car parts. Proper use of a carbide scraper blade can ensure that it lasts for longer periods and provides effective results. In this blog, we will guide you on how to properly sharpen your carbide scraper blade.

1. Choose the right material for your scraper blade:

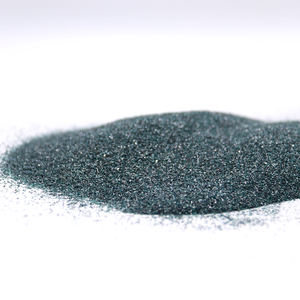

The first step in sharpening a carbide scraper blade is to choose the right material for it. Carbide is a hard and wear-resistant material that can be easily sharpened using traditional methods. Some popular materials used for carbide scrapers include carbon steel, titanium, and ceramic. When choosing the material for your scraper blade, consider factors such as durability, cost, and ease of use.

2. Set up your sharpening machine:

Before sharpening your carbide scraper blade, you need to set up your sharpening machine correctly. This involves selecting the correct sharpening type (e.g., disk, double-disk), setting the appropriate file grits, and aligning the blade with the appropriate grits. Additionally, make sure the machine is well-maintained and free of debris.

3. Hold the blade steady:

When sharpening a carbide scraper blade, it’s important to hold it steady and avoid swaying or wobbling. This will help to achieve accurate and consistent results. To keep the blade steady, place it against a flat surface, such as a work table or countertop, and use your dominant hand to control the movement of the blade.

4. Choose the correct angle:

The angle at which you sharpen your carbide scraper blade is critical to achieving effective results. A proper angle will depend on the specific blade you’re sharpening and the task at hand. Generally, the blade should be aligned with the edge of the surface you want to remove dust or debris from, and the angle should be around 45 degrees.

5. Use the right sharpening method:

There are several sharpening methods you can use, each with its own advantages and disadvantages. The most common methods include using a double-file or a disk-shaped file, as well as using specialized blades designed specifically for carbide. Experiment with different methods to find the one that works best for you.

6. Sand the blade after sharpening:

After sharpening your carbide scraper blade, it’s important to sand the blade to smooth out any rough spots or edges. This will help to prevent any damage to the blade during future use. Start by sanding with a very fine grit sandpaper, then move on to medium-grit sandpaper, and finally to honing compounds.

7. Rebuild your blade:

Finally, if your carbide scraper blade has become dull or damaged, it’s time to rebuild it. This involves cleaning and the blade, applying a special formula designed for carbide, and reshaping the blade according to manufacturer instructions. After rebuilding, reapply honing compounds to bring the blade back to its original shape and sharpness.

(how to sharpen carbide scraper blade)

In conclusion, sharpening your carbide scraper blade requires patience, attention to detail, and the right tools. By following these steps and choosing the right material and sharpening method, you can ensure that your carbide scraper blade stays sharp and performs effectively for years to come. So the next time you need to clean a surface, don’t hesitate to reach for your carbide scraper blade and give it a quick and easy shine!